This blog is the sixth in a series showcasing J&M Plating’s operation, our people, and what makes us a great place to work and do business.

Automated assembly lines require defect-free parts in order to keep the line producing. Fasteners containing foreign material and manufacturing defects can make their way into an automated assembly line and cause serious repercussions. This can cause assembly equipment downtime and the costs associated with that downtime. Shutting down an assembly line to right these wrongs takes time and money and that is something we must avoid at all costs.

Because OEM and Tier suppliers have increased their automated assembly capabilities, we have engineered solutions to identify and remove defective parts that may make their way through to us. We have developed a sorting department, run and managed by experienced people who understand the complexities involved in manufacturing and assembly operations. Most of our trained sorting staff have been in the industry for more than 20 years.

J&M Plating strives to provide personalized customer service, high-quality processing, and a long-term commitment to the success of our customers and our employees. Our ability to provide sorting solutions to the automotive and industrial markets has helped make us a company the fastener industry has confidence in.

The following is an overview of J&M Plating’s most common sorting processing capabilities:

Sorting Processes/Services

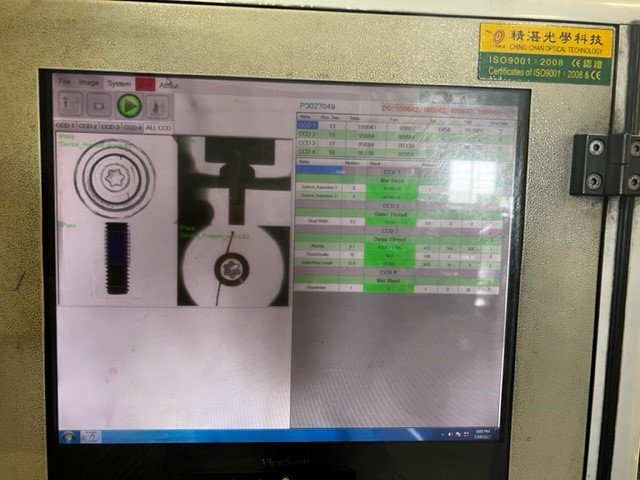

Vision Machines

Eddy Current

Packaging

Labeling

Sorting Capabilities

Foreign Material

Presence of Threads

Shank Length

Head Height

Head Diameter

Cracked Heads

Presence of Washer

Thread Measurement

Major Diameter

Root Diameter

Helix Angle

Pitch Diameter

Recess Sorting

Phillips

6 Lobe

Socket

Broken Punches

Recess Fill